1. Industrie-National

DIN 3770 - Sealing rings (O-rings) with special accuracy made of elastomeric materials. This standard should not be used for new designs.

DIN 3771 Part 1 - Fluid systems, O-rings, sizes to ISO 3601-1. This standard contains sizes and tolerances of O-rings with spe- cial accuracy for general applications in fluid systems.

DIN 3771 Part 2 - Fluid systems, O-rings, testing, marking. This standard applies to DIN 3771 Part 1, testing and marking of O-rings.

DIN 3771 Part 3 - Fluid systems, O-rings, field of application, materials.This standard covers materials, their hardness range and fields of application of O-rings to DIN 3771 Part 1.

DIN 3771 Part 4 - Fluid systems, O-rings, quality acceptance criteria, surface finish and form. This standard covers acceptance criteria for surface finish and form.

DIN 3771 Part 5 - Fluid systems, O-rings, Methods for calculation and dimensions of housings

DIN 65 202 - Aerospace, O-rings, sizes to ISO 3601-1. This standard contains sizes and tolerances which are preferably for use in the aerospace industry.

DIN 65 203 - Aerospace, O-rings from elastomers, technical delivery conditions. This standard is for O-rings from elastomers and intended for use in the aerospace industry when size called up in a drawing, order or specification.

DIN 65 204 (under preparation) - Aerospace, O-rings, design criteria for O-ring grooves.

ISO 3601-1 - Fluid systems, O-rings – Part 1. Inner diameters, cross-sections, tolerances and size coding.

ISO/DIS 3601-2 – (under preparation) Fluid systems, O-rings – Part 2. Design criteria for O-ring grooves.

ISO 3601-3 - Fluid systems, O-rings – Part 3. Quality acceptance levels.

ISO 3601-5 - Fluid systems, O-rings – Part 5. Suitability of elastomeric materials for industrial applications

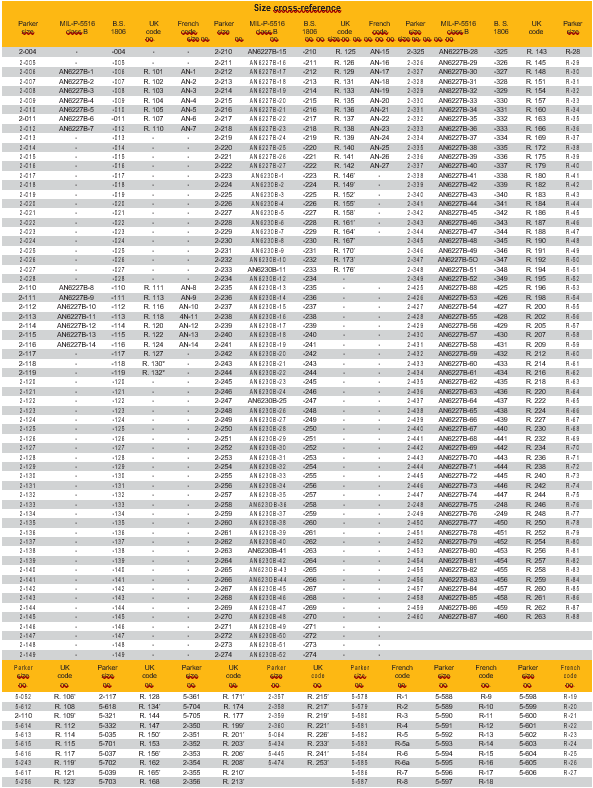

BS 1806 specifies dimensions (inches) for inner diameters and cross-sections and their tolerances including grooves. O-ring dimensions are identical with the Parker 2-xxx series. Table 11.1 gives a cross-reference among the various European standard specifications. BS 4518 specifies dimensions and tolerances together with groove dimensions. Cross-section diameters are: 1.6 / 2.4 / 3.0 / 5.7 and 8.4 mm

France

The following French standards based upon ISO 3601 Parts 1 to 3: NF-T-47-501 is comparable with ISO 3601 Part 1. NF-T-47-502 is comparable with ISO 3601 Part 2. NF-T-47-503 is comparable with ISO 3601 Part 3. French purchase codes R 1 to R 27 are identical with Parker sizes 5-578 to 5-606. R 28 to R 88 are identical with Parker sizes 2-325 to 2-349 and 2-425 to 2-460. For more details, see Euro- pean O-ring codes, Table 11.1.

Italy

A committee for seal and hose standardization exists in the UNI which recommends the use of the American AS 568 B standard specification. In certain areas the French R 1 to R 88 are used.

Sweden

O-rings are standardized under SMS 1586, Swedish military standard. Cross sections 1.6 / 2.4 / 3.0 / 5.7 and 8.4 mm are recommended.

USA

AS 568 B (Aerospace Standard) published by the SAE (Society of Automotive Engineers) specifies sizes and tolerances. The cross-section tolerances correspond to ISO 3601-1 and DIN 3771 Part 1 (within a few hundredths of a millimetre), see Table 11.1.

DIN 7716 - Products from rubber; requirements for storage, cleaning and servicing.

DIN 9088 - Aerospace; shelf-livers of parts from elastomers (un- der preparation).

DIN 24 320 - Fire resistant hydraulic fluids, group HFA-1, proper- ties and requirements.

DIN 51 524 - Hydraulic fluids, hydraulic oils H and H-L; minimum requirements.

DIN 51 525 - Hydraulic fluids; hydraulic oils H-LP; minimum requirements.

DIN 51 600 - Liquid fuels, leaded petroleum oils; minimum requirements.

DIN 51 601 - Liquid fuels, Diesel oil; minimum requirements.

DIN 51 603 Part 1 - Liquid fuels; heating oils, heating oil EL; minimum requirements.

DIN 51 603 Part 2 - Liquid fuels; heating oils, heating oils L. M and S; minimum requirements.

DIN 53 504 - Testing of elastomers; measurement of tensile strength, maximum stress, elongation at break and stress values at tensile test.

DIN 53 512 - Testing of rubbers; determination of rebound resil- ience.

DIN 53 516 - Testing of rubbers and elastomers; determination of abrasion resistance.

DIN 53 522 – Testing of elastomers; determination of resistance to flex-cracking and crack growth.

DIN 53 538 - Standard reference elastomer; nitrile-butadiene rubber (NBR), cross-linked by peroxide to characterise working fluids with respect to their reaction on NBR.

DIN 53 545 - Testing of rubber; determination of the behaviour at low temperature (behaviour to cold), principles, testing meth- ods.

DIN 53 670 - Testing of rubber or elastomers; testing of rubber in standard text mixtures, equipment and procedures.

DIN ISO 34-1 - Testing of elastomers; determination of tear growth, strip specimen.

DIN ISO 48 - Rubber, vulcanized or thermoplastic – Determina- tion of hardness (Hardness between 10 IRHD and 100 IRHD)

DIN ISO 815 - Testing of elastomers – determination of compres- sion set.

DIN EN 10 204 - Certification of material testing.

DIN ISO 1183-2 - Testing of plastics and elastomers; measure- ment of specific gravity.

DIN ISO 1629 - Rubber and latex; difference and abbreviations.

DIN ISO 1817 - Testing of rubber and elastomers; determination of the resistance to liquids, vapours and gases.

DIN ISO 2285 - Rubber, vulcanized or thermoplastic – Determi- nation of tenstion set

DIN ISO 2859 - Procedures and tables for inspection by at- tributes – statistical sampling.

DIN ISO 3302 - Tolerances for products

VDMA 24 317 - Fluid systems; hydraulic, fire-resistant hydraulic fluids, guidelines.

LN 9214 - Aerospace; toroidal sealing rings (O-rings) for solder- less tube fittings with coupling sleeves, flareless.

ASTM D 395 B - Compression set under constant deformation in air. Specimen: type 1 29 dia x 12.5 mm type 2 13 dia x 6 mm.

ASTM D 412 - Rubber properties under tensile test; tensile strength, elongation, modulus.

ASTM D 471 - Rubber properties; influence of contact fluids.

ASTM D 1329 - Evaluating rubber properties; retraction at low temperatures (TR test).

Ordering addresses: