Quality

It is in the interest of Parker to supply products and services which meet the quality requirements of our customers.Adopting the definition of DGQ, Deutsche Gesellschaft für Qualität (Ger- man Society for Quality) it is our policy to produce quality through selecting the best materials, optimum production methods, se- vere test procedures and continuous training of our employees to manufacture quality:

Our extensive Quality System is designed to rule out influences which negatively affect the quality of our products. Product qual- ity must be produced and not inspected into a finished product at the final inspection. Our Quality Handbook is a document which presents our procedures and shows quality assurance from raw material reception through production processes and storage to dispatch. It describes the actual techniques necessary to achieve the requirements.

DIN EN ISO 9001 certified since 1993 and ISO/TS 16949 since 2002.

Evaluation criteria for O-rings

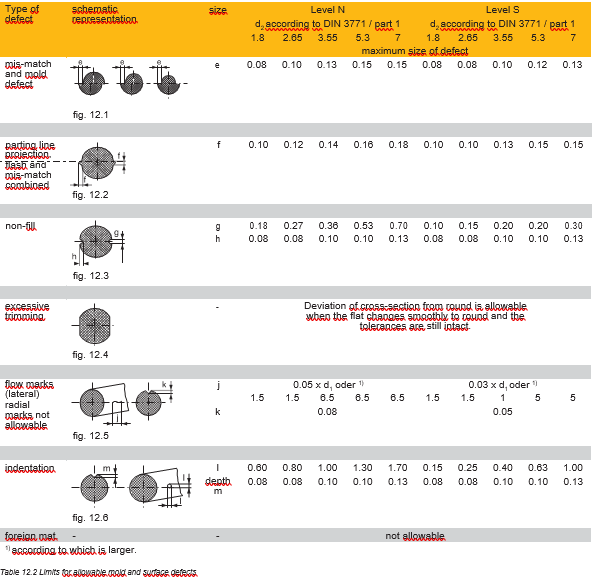

The criteria governing the evaluation of surface defects in O-ring seals are defined under DIN 3771 Part 4, see Table 12.1. The size of allowable defects is quantified in Table 12.2 and subdi- vided into levels “N” (Table 12.2 N) and “S” (Table 12.2 S). This subdivision corresponds to levels “B” and “A” in the American MIL Standard 413.

The limiting values for allowable O-ring surface defects are laid out to requirements for industrial applications. The defect size is related to the O-ring cross-section and is small enough to not af- fect the function. Precision O-rings from Parker are inspected to level N to insure a high degree of safety.

In special applications, e.g. in the aerospace industry, it is neces- sary to limit surface defects to sizes smaller than allowed for by level N. This increased quality level can be achieved through a more intense quality assurance programme in production and inspection departments. To order the increased quality standard, level “S” must be stated together with the application. Our standard production is checked to level N.