As a manufacturer of O-rings we can produce any O-ring size equired. However, from the economic point of view it is important to select from standard sizes available ex-stock, particularly our 2-xxx series. Our 2-xxx series complies with American Standard AS 568 B and is recognized worldwide. These sizes also have been adopted by DIN 3771 Part 1 and ISO 3601 Part 1.

The 2-xxx series from Parker provides two particular advantages to the user:

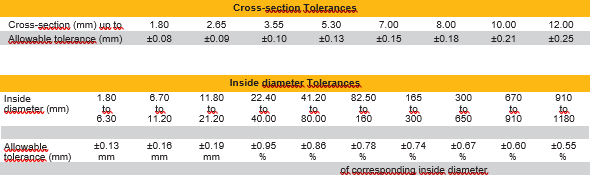

An O-ring seal is designed to Section 2 taking into account design, O-ring size, stretching (or compression) of the O-ring circumference, and deformation of the cross-section. Small deviations from our design recommendations which do not lead to leakage or failure often are possible. If you have any doubt please contact our application engineers for further advice. Tolerances Parker precision O-rings are manufactured to very narrow toler- ances. These tolerances are standardized in DIN 3771 and ISO 3601-1 (up to 7 mm cross-section and 670 mm inner diameter). The tolerances laid down in the following tables are specific for nitrile butadiene rubber O-rings, hardness 70 IRHD. For other compounds, individual material shrinkage factors could lead to different tolerances and designs. If with variation of compound and hardness, the ability to function is affected, it is necessary to manufacture a corresponding mould to remain within the speci- fied tolerance band.

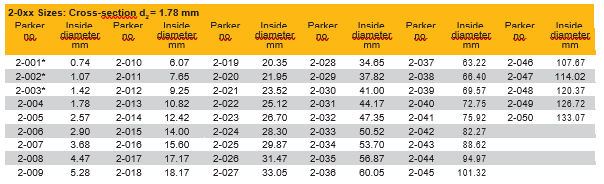

Example of order:

For Parker precision O-rings:

Inner diameter: 14.00 mm

Cross-section: 1.78 mm

Compound: 674-70 (NBR 70 Shore A) O-ring, 14 x 1.78, 2-015, N 674-70