Introduction

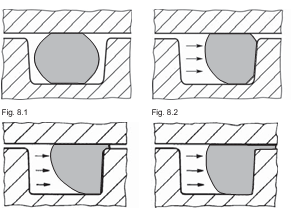

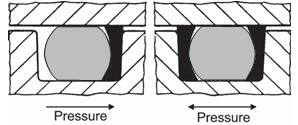

The Parker Parbak is a supplement to pressure seals such as an O-ring. It is not a sealing ring in itself. The primary reason for the use of a back-up ring is to reduce the clearance gap on the low pressure side of an O-ring or similar type of seal. An O-ring and Parbak combination will withstand much higher pressures than an O-ring alone. Parker Seal´s Parbak® back-up rings are outstanding for several reasons. To begin with, Parbaks® are moulded in a hard rubber compound in one continuous circle, yet they can be stretched easily into place. Because they are not split or spiralled, Parbaks® do not cause the localized wear on O-rings which is characteristic of other types of back-up rings.

Parbaks® have proved to last longer with greater reliability than other types of back-up rings tested. Parbaks® extend the op- erating pressure range of O-rings or other types of seals. The additional benefit of increased lubrication of the O-ring may be also obtained because the Parbak® will trap small amounts of lubricant between itself and the O-ring.

The use of Parbaks® permits a far greater metal-to-metal clear- ance between moving parts. This helps overcome difficulties encountered with wide or out-of-tolerance bores and shafts.

The elastic nature of O-ring seals and the clearance reducing capability of the Parbak® offers an important cost reduction op- portunity. In many applications, machining tolerances can be increased at considerable savings in time and money

Design information

Hardness must be considered when choosing an O-ring. For most seal applications optimum performance is achieved with a 70 Shore A durometer compound. Generally, O-rings in this hardness range seal well at low pressures. However, they are more liable to extrusion at high pressure than harder rubber parts. O-ring seals which exceed a Shore A value of 85 durometer are seldom successful in dynamic applications because the harder materials do not follow irregularities or deformations in the sealing surface (e.g. cylinder wall). Hence, harder O-rings tend to permit leakage, particularly at low pressures. Using Parbaks® is a simple way to obtain the low pressure sealing ability, wear and abrasion resistance of the lower durometer O-rings plus the high pressure extrusion resistance of a hard compound. Standard Parbak® com- pound N 300-90 hardens further at elevated temperatures enhancing its extrusion resistant quality.

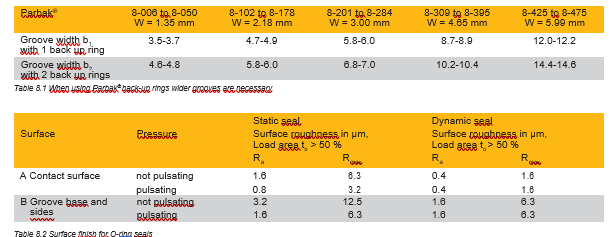

The surface finish for dynamic applications should be taken from Table 8.2. In general it can be said that the working lifetimes of both O-rings and Parbaks® are extended by im- provement of the surface finish. The surface finish roughness should in any case not be less than Rmax = 0.5 mm because a lubricating film needs to be encouraged. Rapid wear is the result of an insufficient lubricating film.

The O-ring and the Parbak® must be selected to suit the ap- plication and considering all factors (e.g. pressure, tempera- ture, contact medium, velocity, size, etc.).

Allowable range of pressure

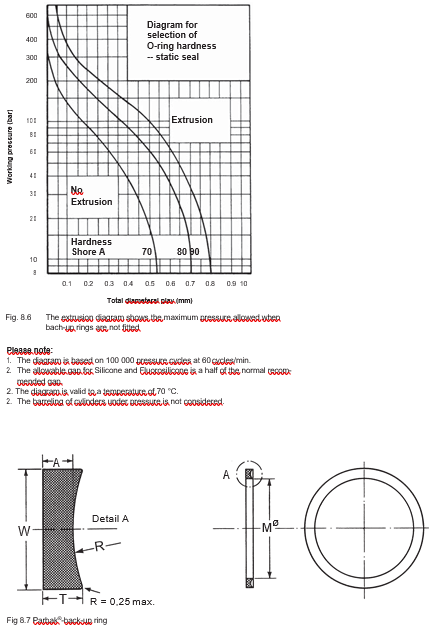

Fig 8.6 shows the extrusion characteristics for elastomers of dif- ferent hardnesses. When considering the risk of extrusion at a particular pressure and diameter clearance gap, the tendency of metal parts to “breath” under fluctuating pressures cannot be ignored. The total play in diameter must be taken because in general eccentricity is to be expected within limits.

Example: O-ring compound: N 674-70 (70 °Shore A)

Working pressure: 100 bar

Play in diameter: 0.36 mm max to drawing tolerances and 0.40 mm when “breathing”

An O-ring of 70 Shore hardness would tend to be forced into a diameter gap of 0.4mm by a pressure of appr 38bar. When Parbak® back-up rings (nominal hardness 90 Shore A) are used, in addition to the O-ring, a maximum pressure of 140 bar is al- lowable. In addition to pressure and temperature, other factors play an important role in interpreting the extrusion diagram. To allow for these influences (e.g. of temperature and wear), a safety factor is necessary.

Compounds

Parbaks® are available as standard in compound N 300-90, an elastomer based on acryl-nitrile butadiene rubber (NBR) with a hardness of 90 Shore A. Its physical properties make it suitable for most applications: wide temperature range, correct hardness, long life, compatibility with a wide range of media including near- ly all hydraulic fluids but not including fire-resistant fluids such as Skydrol, Pydraul, Houghtosafe, Hydrodrive, etc. N 300-90 also is compatible with air and water. The working temperature range is between -55°C and +105°C.

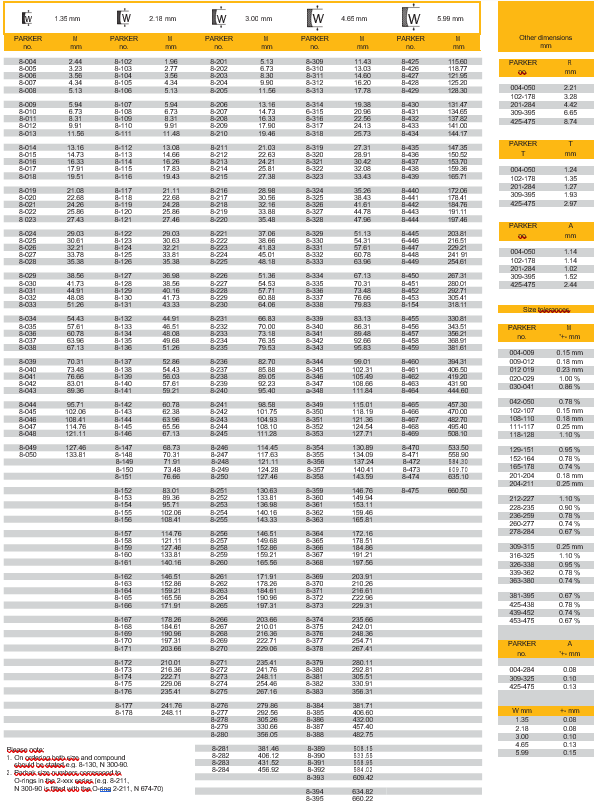

For particular applications, Parker has developed other Parbak materials in compounds possessing special properties, e.g. E 625-90 (ethylene-propylene) or V 709-90 (fluorocarbon). Parbak® standard sizes (8-xxx series) with tolerances for A, M, R, T and W (Fig 8.7) can be taken from the table “Back-up ring standard sizes”.