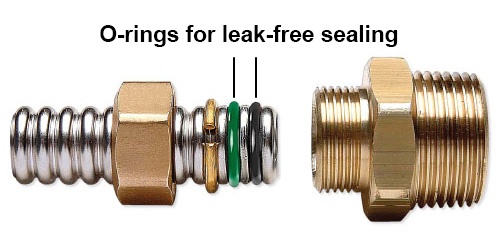

An O-ring, which is also called a packing or a toric joint, is a mechanical gasket in the shape of a torus. It is a donut shaped gasket that is designed to be seated in a groove during assembly between two or more parts to create a leak free seal between the two separate components.

O-ring are produced in many, many materials. The o-ring materials which we sell are NBR, FKM, EPDM, VMQ, HNBR, FFKM, FVMQ, FEPM, ACM, CR, SBR, CSM, ECO, BR, IIR, IR, AU, EU, NR and seamless FEP sheated.

O-rings are standardized in the DIN ISO 3601 (formally DIN 3771). The simple form and reliability of the sealing function of the o-ring is genius, hence why the o-ring is the most used sealing all across the globe!

O-rings are used in many different ways and many different industries. Within separate applications there is made distinction between static (relatively no friction between the to be sealed machine parts) and dynamic (the two machine parts are moving towards each other). The biggest share of o-rings are used for sealing static or slowly moving machine parts.

Industries in what o-rings are greatly used are:

To measure an o-ring you need a few dimensions. First of all you want to know to innerdiameter of the o-ring. Once you know this you also want to know the wallthickness. These two sizes will tell you exactly how big the o-ring is. The only thing you need to determine now is what material suites your applications the best. Have a look at our chemical resistant guide to see what material is suited for your application!